Press Releases

March 28, 2019

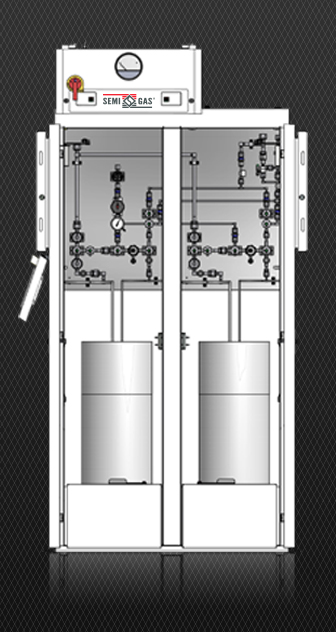

Applied Energy Systems Equips Its Standard SEMI-GAS® Xturion™ LPX™ System to Support Tetraethoxysilane Liquid Source Applications

LPX™ Platform Can Now Be Used to Evaluate and Implement Changes to TEOS Source Material

MALVERN, PA, MARCH 28, 2018 — Applied Energy Systems (AES), provider of high and ultra high purity gas systems, services, and solutions – including design, manufacturing, testing, installation, and expert field services – has equipped its standardized SEMI-GAS® Xturion™ LPX™ (Liquid Push System) with several new capabilities to support the supply of tetraethoxysilane (TEOS) liquid source material for ultra high purity applications.

Through several small modifications and additions, AES was able to build upon its proven LPX™ platform and accommodate specialized requirements for TEOS handling. TEOS requires a dry, low pressure environment and therefore the system uses an external vacuum source – which can be supplied by AES or by the customer – to produce a base pressure of less than 80 mTorr. Integration of a Pirani gauge ensures this vacuum level remains in range, where it is sufficient for purging, and a PLC-based safety interlock switch prevents over-pressurization of the vacuum lines.

Additionally, a degasser was added to remove dissolved gases in the process liquid, including from the push gas or other pad gases. A liquid level switch blocks liquid from entering the vacuum system and protects against degasser failure. By placing the degasser downstream from process line isolation valves, AES preserves process integrity during cylinder changes, maximizing uptime and minimizing wasted product.

“When a customer came to us with their unique TEOS application, we knew that with some minor augmentations, our standard Xturion™ LPX™ system could effectively handle it,” said Jim Murphy, General Manager of Applied Energy Systems. “What’s great about the LPX™ platform is its flexibility to support very diverse liquid source and distribution requirements – giving our customers the discrete capabilities they need without having to develop a fully custom solution.”

Several examples of that flexibility are embodied in AES’ modified LPX™ system for TEOS, including:

- The option to use an AES-supplied or customer-supplied external vacuum source, either of which can be integrated with the system’s PLC controller.

- A design that accommodates many different degasser sizes, depending on system and application needs.

- Lockable, extendable shelf options for cylinders up to 300lbs to ease with the loading and unloading of cylinders.

Customers interested in the SEMI-GAS® Xturion LPX™ for TEOS or other liquid delivery applications can contact AES at semi-gas@appliedenergysystems.com for more information.

###

About Applied Energy Systems

Applied Energy Systems (AES) is the premier provider of high and ultra high purity gas systems, services, and solutions. Since 1968, customers have turned to AES for high-value systems engineering – including design, manufacturing, testing, and field services. Whether equipment requirements are driven by regulation, innovation, or both, AES brings together its specialized engineering capabilities and vast scope of product offerings to create the gas delivery solutions that meet business-critical process demands.

With two industry-leading equipment divisions, SEMI-GAS® and VERSA-GAS™, AES addresses high purity and ultra high purity gas delivery needs for a diverse range of rigorous applications, including semiconductors and electronics, pharmaceuticals and biotechnology, photovoltaics, manufacturing, research laboratories, universities and more. For more information, visit www.appliedenergysystems.com.