Press Releases

August 31, 2016

Applied Energy Systems Launches ‘Applied Excellence’ Initiative as Formalized Program for Continuous Operational Improvement

Company Implementing Accredited Methodologies, Education and Training Programs, and Quality Metrics to Reach New Levels of Efficiency, Sustainability, and On-Time Delivery

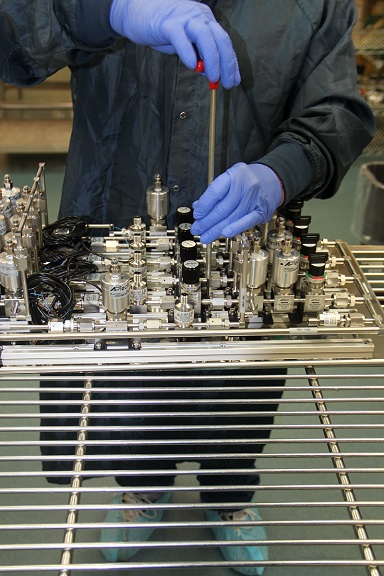

MALVERN, PA, AUGUST 31, 2016 — Applied Energy Systems (AES), provider of premier high and ultra high purity gas systems, services, and solutions – including design, manufacturing, testing, field and precision welding services – has formalized a program for continuous operational improvement through the launch of its ‘Applied Excellence’ initiative. The program was developed by AES to further enhance its business processes using accredited methodologies to improve efficiency, safety, product quality, on-time delivery, and overall team performance. Specifically, the company has been applying principles of Lean Manufacturing, 5S, Value Stream Mapping, and Kaizen, as well as implementing employee education and training programs to ensure sustainability, establish performance metrics, and institute more rigorous accountability practices. In the short time since Applied Excellence was launched, AES has been able to reach and maintain a 97% on-time delivery rate– proof that the initiative is already working, and putting the company well on track to achieve 100% on-time delivery.

“We are excited to see the improvements that the Applied Excellence initiative has already helped us achieve,” said Jim Murphy, General Manager of Applied Energy Systems. “It is enabling us to build upon the strong foundation of people and processes that we have in place, by giving us solid goals and the metrics to track our progress toward them. Now we can more easily spot areas for improvement, and accelerate our efforts to correct and optimize performance moving forward.”

In fact, many initiatives that have already been executed as part of Applied Excellence are helping AES maintain its current high on-time delivery rate. An overhaul and reorganization of both physical and electronic inventory was performed, and implementation of the 5S methodology has helped to optimize manufacturing spaces and streamline production processes. Modified design guidelines, updated project tracking methods, new Bills of Materials, and product routing structures have already improved efficiencies in engineering and manufacturing’s material requirements planning. Additional sales staff have been added to enable faster response times to proposals, customer requests, and internal feedback loops. On the quality side of continual improvement, AES has added an additional stage of quality checks into its production line and enhanced the requirements of its sample validation testing program. The company is now also in the process of taking all current staff, and any new hires, through a formal training program on corporate policies, safety, and work instructions, giving them consistent tools and knowledge needed to work optimally within their role, and ensure positive customer interactions.

“We’re always looking for ways to better serve our customers and further our success as a company,” noted Murphy. “Applied Excellence is helping us to focus in on the most high-return initiatives to achieve both those objectives. We now have a clear roadmap for taking operational excellence, team member engagement, and customer satisfaction to the next level.”

###

About Applied Energy Systems

Applied Energy Systems (AES) is the premier provider of high and ultra high purity gas systems, services, and solutions. Since 1968, customers have turned to AES for high-value systems engineering – including design, manufacturing, testing, and field services. Whether equipment requirements are driven by regulation, innovation, or both, AES brings together its specialized engineering capabilities and vast scope of product offerings to create the gas delivery solutions that meet business-critical process demands.

With two industry-leading equipment divisions, SEMI-GAS® and VERSA-GAS™, AES addresses high purity and ultra high purity gas delivery needs for a diverse range of rigorous applications, including semiconductors and electronics, pharmaceuticals and biotechnology, photovoltaics, manufacturing, research laboratories, universities and more. For more information, visit www.appliedenergysystems.com.

Media Contact:

Megan Kasper

Applied Energy Systems

610.647.8744

mkasper@appliedenergysystems