Press Releases

August 30, 2018

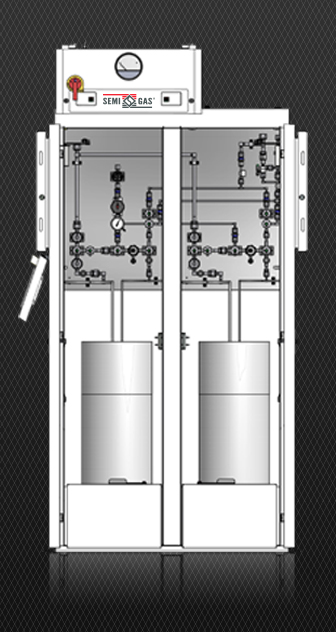

Applied Energy Systems Standardizes Its SEMI-GAS® Xturion™ LPX™ System for Ultra High Purity Liquid Applications

The Push System Supports a Variety of Chemical and Materials Processes Requiring Liquid Delivery

MALVERN, PA, AUGUST 30, 2018 — Applied Energy Systems (AES), provider of high and ultra high purity gas systems, services, and solutions – including design, manufacturing, testing, installation, and expert field services – introduced a standardized version of its SEMI-GAS® Xturion LPX™ (Liquid Push System) for use in a number of ultra high purity hazardous liquid applications. The system combines the most necessary and sought-after safety and performance features requested by customers into one streamlined, standardized model. “After we built our original custom Xturion™ LPX™ design, we had customers asking to have it further tailored to fit their own needs,” said Jim Murphy, General Manager of Applied Energy Systems. “Through multiple custom design iterations, we gained a lot of valuable in-field experience and insights from customers as to what their liquid delivery applications demand. We were able to apply these insights to optimally engineer our standardized LPX™ model.”

The Xturion™ LPX™ supports a diverse range of processes requiring liquid delivery, including those used in materials, chemical, and semiconductor research and manufacturing. It utilizes a push gas to safely deliver the liquid to a point-of-use and includes a custom secondary liquid containment enclosure and splashguard for protection in case of a spill or vessel rupture. The enclosure’s recessed design and latching doors allow for continuous exhaust flow and easy operator access to the source vessels during change-out procedures. Additional design features of the Xturion™ LPX™ include:

- A GigaGuard™ PLC Controller with 9” color touchscreen, providing an intuitive interface to configure automatic purging, cylinder switchover, and system monitoring processes.

- Liquid level detectors and sensors tied into the system’s GigaGuard™ PLC Controller to safeguard against hazardous spills or releases.

- Transducer-based pressure monitoring to signal an alarm in case of an undesirable system condition.

- Analog cylinder scales to precisely weigh and record cylinder contents, as well as trigger the system’s automatic cylinder switchover.

- Optional Toxic Gas Detection Kit for continuous toxic gas monitoring and integration into a facility monitoring system.

- A Magnahelic and Switch Exhaust Monitor to indicate air and exhaust pressure differentials.

- Separate push and purge gas inlets for added end user flexibility.

Customers interested in the SEMI-GAS® Xturion LPX™ for their liquid gas applications can contact AES at semi-gas@appliedenergysystems.com for more information.

###

About Applied Energy Systems

Applied Energy Systems (AES) is the premier provider of high and ultra high purity gas systems, services, and solutions. Since 1968, customers have turned to AES for high-value systems engineering – including design, manufacturing, testing, and field services. Whether equipment requirements are driven by regulation, innovation, or both, AES brings together its specialized engineering capabilities and vast scope of product offerings to create the gas delivery solutions that meet business-critical process demands.

With two industry-leading equipment divisions, SEMI-GAS® and VERSA-GAS™, AES addresses high purity and ultra high purity gas delivery needs for a diverse range of rigorous applications, including semiconductors and electronics, pharmaceuticals and biotechnology, photovoltaics, manufacturing, research laboratories, universities and more. For more information, visit www.appliedenergysystems.com.