Press Releases

May 31, 2016

Applied Energy Systems Supports Growing Need for Custom Gas Delivery Solutions in the Sulfuric Acid Industry

Systems Provider Offers Custom-Tailored Applied Solutions to Meet the Unique and Evolving Process Demands of Sulfuric Acid Plants

MALVERN, PA, May 31, 2016 — Applied Energy Systems (AES), provider of high and ultra high purity gas systems, services, and solutions – including design, manufacturing, testing, field and precision welding services – is supporting the increasingly complex process demands of the sulfuric acid industry with its custom-adapted high and ultra high purity gas delivery systems, known as Applied Solutions. These offerings enable sulfuric acid plant operators to tap the proven quality of AES’ standard equipment brands, SEMI-GAS® and VERSA-GAS™, but then tailor those core products to the specifications that will meet their unique production requirements.

“The sulfuric acid industry is continually evolving, and we’ve recently seen an increase in the demand for gas delivery solutions that can support very specific conditions for testing and analysis,” Jim Murphy, General Manager of Applied Energy Systems. “Through our Applied Solutions, we can custom-engineer our existing line of systems—all of which are renowned for their quality, safety, and reliability—to include the discrete functionality that these customers’ unique processes require.”

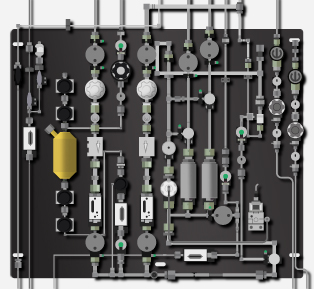

One recent example of such an Applied Solution is the Activity Tester Cabinet for sulfuric acid. The system, configured with one mixing cabinet and one 1-cylinder source cabinet, is equipped with:

- A transducer based pressure monitoring system, differential pressure gauge, and switch exhaust monitor to ensure adequate exhaust flow.

- A Venturi Vacuum generator to allow for evacuation of the manifold during purge sequences down to approximately 100 torr.

- One process panel for 8% SO2, with fully automatic purge capability to increase efficiency and decrease human error.

- A fully redundant silica bypass manifold with dual isolation to remove impurities prior to chromatograph analyzing. The manifold’s design provides two points of isolation between the hazardous gas and the operator during any maintenance routines and also allows one silica pack to be cleaned and/or replaced while in remaining in operation.

- Filters to remove particles down to 0.003 micron, and a purifier to remove impurities in process gas prior to mixing.

- Mass Flow Controllers and a Static Gas Mixer to accurately monitor and deliver homogeneous gas mixtures.

- A Micro Gas Analyzer for instantaneous and accurate analysis of the gas sample.

Murphy sees the company’s ability to serve evolving needs as not only a benefit to customers, but to AES as well. “We continually challenge ourselves to solve the application challenges of the industries we serve. In this case, our engineers have immersed themselves in how to help sulfuric acid plants achieve optimal output, and are building customized solutions to support that goal. While the Activity Tester Cabinet is a custom system, we can take what we’ve learned from that product development effort and apply it to the needs of other plant customers. By continually helping our customers innovate and evolve, we’re innovating and evolving our own gas delivery system offerings in new and exciting ways.”

###

About Applied Energy Systems

Applied Energy Systems (AES) is the premier provider of high and ultra high purity gas systems, services, and solutions. Since 1968, customers have turned to AES for high-value systems engineering – including design, manufacturing, testing, and field services. Whether equipment requirements are driven by regulation, innovation, or both, AES brings together its specialized engineering capabilities and vast scope of product offerings to create the gas delivery solutions that meet business-critical process demands.

With two industry-leading equipment divisions, SEMI-GAS® and VERSA-GAS™, AES addresses high purity and ultra high purity gas delivery needs for a diverse range of rigorous applications, including semiconductors and electronics, pharmaceuticals and biotechnology, photovoltaics, manufacturing, research laboratories, universities and more. For more information, visit www.appliedenergysystems.com.

Media Contact:

Megan Kasper

Applied Energy Systems

610.647.8744

mkasper@appliedenergysystems.com