The Art of System Component Selection, Down to a Science

Here at AES, there is nothing “standard” about our line of gas delivery equipment solutions. This fact is true not just for our custom-engineered Applied Solutions, but for our standard SEMI-GAS® and VERSA-GAS™ systems as well. Our talented team of mechanical, chemical, materials, and electrical engineers sizes and specs each component of our standard lines of high and ultra high purity gas delivery systems during every build, to ensure we meet each customer’s unique industry and application requirements, every time.

While the competition sells their gas delivery equipment in one rigid variety, we take pride in providing solutions that work optimally in our customers’ environments, and are built to uphold their unique operational, regulatory, and business demands.

We have this process down to a science.

With almost 50 years of experience partnering with our valued customers, AES is committed to applying our years of gas delivery and vertical expertise to our customers’ project needs. By understanding your unique requirements early in the process, we can ensure your solution is built from the ground up to achieve the standards of safety, precision, and quality you demand. Our engineering teams work together to expertly select the right-fit components, and are able to do so in a streamlined timeframe so that you can begin to implement our solutions and realize the benefits as quickly as possible.

Let’s take a look into the process that we follow to specify standard system components:

- First, we request cylinder size, cylinder connection, maximum flow rate, and delivery pressure information from the customer at the time of order placement.

- During our initial project kick-off, we analyze the above information and begin to specify the best system components to be included within the solution.

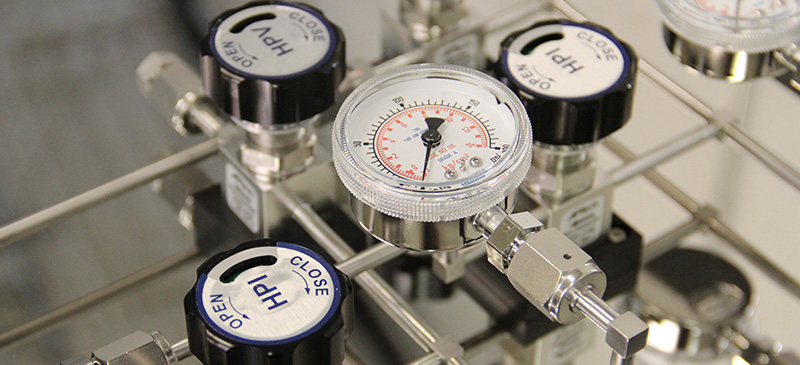

- To begin specification, we determine the appropriate UHP springless diaphragm valves per Cv (flow rate) rating.

- Once the valves are selected, we choose the cylinder, delivery, and purge transducers in the proper pressure range for the project.

- We then also select excess flow switches to alarm above the maximum desired flow rate, making sure they are configured in the proper range.

- Then, we determine which tied diaphragm regulators to include for optimum performance in the desired pressure range.

- Next, we design 316 L stainless steel rigid pigtails to marry the process and purge panels perfectly with the customer’s cylinder dimensions and connections.

- Lastly, we identify any additional safety features required for the delivery of hazardous, toxic, or corrosive gases and make recommendations for inclusion of those additional components as needed.

Precise Component Selection. Desirable Lead Time. Comprehensive Gas Delivery.

Each of the above steps contributes to designing a comprehensive gas delivery system fit for our customers’ needs. Whether you are looking for a premier, production-ready solution for your most specialized and rigorous gas delivery needs, or a cost-effective solution without tradeoffs in safety and quality, you’ll be sure to find the gas delivery system that works for you within our standard SEMI-GAS® and VERSA-GAS™ lines.

Our thorough approach to component selection is a key differentiator that you won’t find from other system providers. Don’t settle for less than the best. Contact AES today to learn more about our offerings and how we are committed to delivering systems that are fit for your needs and requirements.

Share this Post: