Growing Manufacturing Pressures and the Rise of Bulk Gas Delivery: What’s the Correlation?

Between 2010 and 2016, manufacturing output increased by 10-20%. Specifically in the semiconductor industry, this trend is reflected in the recent record-high growth seen in fab equipment spending, with investments being made in facilities expansion to meet growing market demand; but it also reveals a trend that fabs are relying more heavily on their equipment to push the boundaries of their processing speed and output volume.

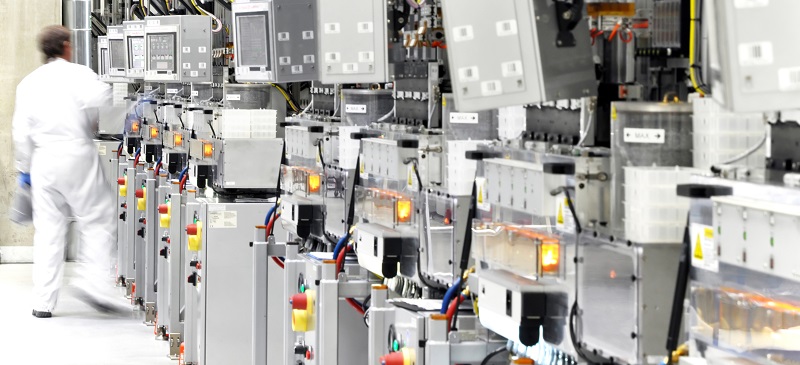

When it comes to gas delivery, manufacturers are looking to systems that can maximize their production time by supplying their specialty process gases in both higher volumes and at higher flow rates. The type of equipment that can handle these demands requires additional storage and component sizing considerations as well as specific purification and heating capabilities, and in turn we at AES have seen a notable increase in requests for our SEMI-GAS® Megaturion™ Bulk Specialty Gas Delivery Systems.

While the trend toward seeking out bulk gas delivery systems is apparent, many of the root pressures leading to this movement are less so. Here are some of the driving factors we’re seeing lead to the greater emphasis on high-volume gas delivery today:

Pressure to Improve Internal Production Processes

Reports indicate that improving internal production processes is the top challenge manufacturers experience today. Fabs are under increased pressure to deliver more products, more rapidly, all while maintaining a high level of accuracy. They are also evolving their processes to support new technologies and advance wafer innovation, and those processes require more gases than ever before. Gas delivery systems that can handle higher gas volumes enable operations to move faster, which allows fabs to keep to prescribed schedules, and deliver the sheer quantity of gases needed to support process advancements.

But quantity can’t be a substitute for quality. These high volume systems must still be able to precisely deliver gases at consistent, sustained high flow rates, and give operators the flexible control they need to enable continuous process optimization.

Pressure to Deliver for Large and Small Manufacturers Alike

Fab footprints are expanding, and wafer sizes are too. As facilities continue to introduce new tools into their environments to support increased wafer output, their need to handle larger quantities of gases also grows. The large Tier 1 leaders must constantly evolve to remain at the top of the market, and equipment that supports gas delivery at scale can help them to address some of their top priorities, such as improving demand responsiveness, reducing annual costs, and streamlining supply chain performance.

But the benefits of bulk gas delivery are not limited to the top global semiconductor leaders. Smaller plants report struggling to achieve economies of scale and productivity boosts of advanced manufacturing. By installing systems that have the capacity to handle high volumes of specialty gases, and the durability to consistently and purely deliver them at high flow rates, fabs on the rise can take advantage of increased throughput capabilities and new time savings.

Pressure to Maintain Safety in a Fast-Paced Environment

Fabs are moving faster than ever before as process improvements and technology innovations help streamline manufacturing processes at every step. But the rapid speed of operations also presents new safety risks, and facilities must balance the desire for quick turnaround with the mandate for safety at all times. A key benefit of bulk gas systems, like our Megaturion™ Source System and Megaturion™ MegaCyl system, is that they require less operator interaction because cylinder change-outs are less frequent. This keeps processes streamlined, running without manual intervention for longer, while minimizing operator exposure and risk.

We believe that it is important to understand the underlying factors that are driving shifts in our product demand, as it will better enable us to meet the real challenges that our customers face. If you’d like to discuss your unique manufacturing concerns or opportunities related to gas delivery with AES’ engineers, we’d be happy to start a conversation with you today.

Share this Post: