Supporting Innovation at Brookhaven National Laboratory: A Closer Look

National laboratories are responsible for various, high-stakes government R&D projects that are critical to the advancement of our nation. These labs are hubs of data and innovation, making key discoveries in science and technology that aim to create better and brighter futures.

The complicated experiments run within these laboratories often require the use of a variety of specialty process gases – from inert to toxic, highly toxic, corrosive, flammable, pyrophoric, and other hazardous classified gases – each with their own unique properties and requirements for safe monitoring and precise handling. Carrying out such experimentation with the highest possible accuracy and safety demands advanced gas delivery equipment and systems that are flexible enough to support changing experiment parameters, without compromising performance or reliability. But even more than that, labs like these require a gas delivery equipment partner that understands their unique research environments and how the systems must operate within their process, regulatory, and testing frameworks.

AES’ ongoing partnership with Brookhaven National Laboratory is just the latest example of our ability to provide both the gas delivery systems and services needed to optimally support lab innovation efforts. In this blog we take a closer look at how we are helping to develop a third comprehensive Gas Handling System (GHS) for Brookhaven’s X-Ray Powder Diffraction (XPD) Beamline.

The Need: Diverse Gas Handling Capabilities to Support R&D Advancements

Brookhaven’s National Synchrotron Light Source II (NSLS-II) is one of the most advanced synchrotron facilities in the world for X-ray imaging and high-resolution energy analysis, enabling the study of material properties and functions with nanoscale resolution and sensitivity. NSLS-II is being used to accelerate major advancements in materials that will enable new energy technologies, from nanocatalyst-based fuel cells to next-gen nuclear power systems. The XPD beamline is included in the NSLS-II facility and consists of three experimental hutches to which a variety of gases must be supplied in order to create the proper sample environments. What the lab needed was a comprehensive gas handling system that could safely and flexibly support those gas supply requirements, and they turned to AES for the job.

The Solution: Comprehensive GHS, with AES Engineering Innovation Applied

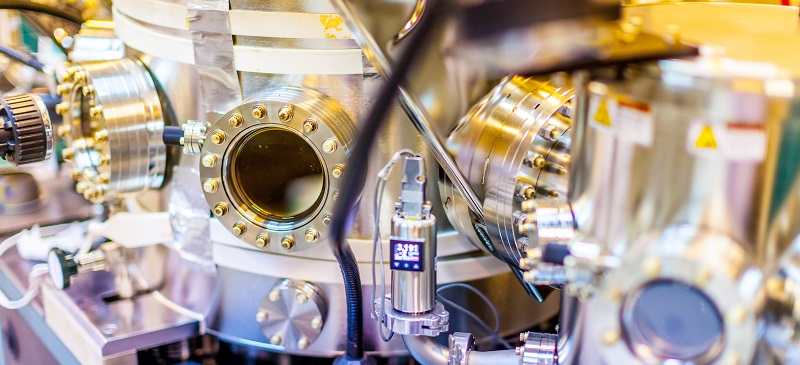

AES is supporting the build-out of various gas delivery system components for Brookhaven, all of which are engineered to work together as one comprehensive GHS. Much of this was accomplished by leveraging solutions from our VERSA-GAS™ line of vSource™ Gas Source Systems, including fully and semi-automatic gas cabinets, gas panels, and rack mount systems. But because the lab needed to safely support a wide range of flow rates and pressures, including different gas types, Brookhaven had a number of custom equipment needs as well. Our team was able to accommodate these requirements through our Applied Solutions process, combining our knowledge of laboratory environments with deep equipment engineering expertise to deliver systems that are tailored to uphold their specific beamline experimentation demands. These solutions include Mass Flow Controller panels and enclosures; temperature-controlled bubbler enclosures; a custom Toxic Gas Detection System (which integrates fully with Brookhaven’s Facility Monitoring System); and a customized ‘Master’ Programmable Logic Controller (PLC) to safely monitor (and shutdown) each sub-system of the GHS. All interoperate to give Brookhaven researchers a seamless, flexible, and safe solution to manage their diverse gas handling needs.

Partnering for Progress

We are excited to play a role in supporting Brookhaven’s work toward uncovering new energy innovations. A piece of this partnership includes ensuring that the systems we deliver operate optimally within the laboratory. As such, we will be delivering a full suite of Applied Services including ultra high purity interconnect piping, equipment installation, commissioning, and training. We are committed to helping the lab work through the challenges of experimentation by bringing their gas delivery requirements to life!

Share this Post: